OSP process for PCB manufacture

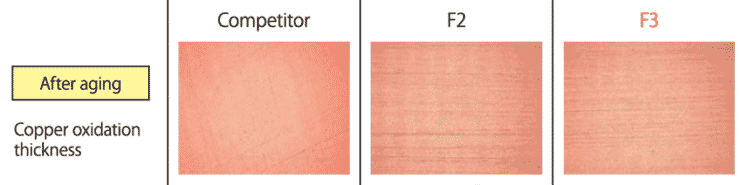

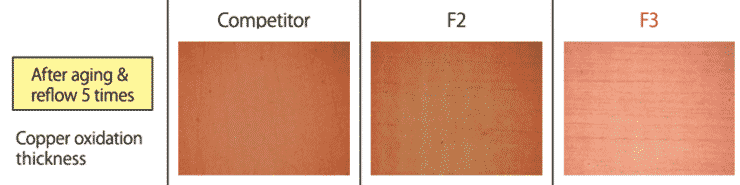

The GLICOAT® range is a one-step OSP (Organic Solder Preservative) for PCB manufacture. By chemically reacting with copper, the active ingredient, a substituted imidazole derivative, GLICOAT®, produces a uniform, very thin and transparent organic coating on copper surfaces and in though holes in PCBs. The surface is suitable for lead-free assembly and multiple soldering.

GLICOAT® coatings have excellent heat resistance, are planar and compatible with “non-clean soldering fluxes” and lead-free solder pastes. They are optimally suited for use with PCBs and SMD technology as well as an alternative to HAL and other final surfaces. GLICOAT® can be applied horizontally and vertically and is particularly environmentally friendly.

System profile

- Uniform, semi-matt and planar deposition

- RoHS compliant, lead-free

- High stability against contamination

- Whisker inhibited

- Low viscosity for optimal wetting

- Stabilised against the formation of Sn(4+)

- Very good solder mask compatibility

Application profile

- Can be applied horizontally and vertically

- All components can be analysed

- Low working temperature

- Very good rinseability

OSP (Organic solder preservative)

GLICOAT® (OSP) creates a uniform, very thin, transparent and solderable organic coating on copper surfaces and in through holes in PCBs. Depending on the application, different variants are available.