100% sorting

WE ENSURE QUALITY RIGHT TO THE END

Assembly and testing

The whole is more than the sum of its parts

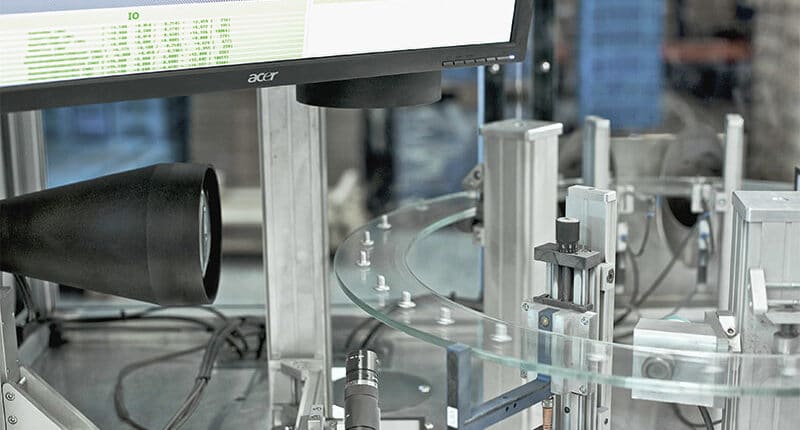

Another offer from our full service area is manual component assembly. This service, in addition to the riveting and pressing processes, includes the application of labels, clips and protective caps. As a complete service, we offer the completion and inspection of your assembly directly after the coating, labelling according to the VDA standard, and the delivery of your goods directly to the OEMs. A very useful service both economically and ecologically. We also offer 100% quality checks by visual inspection for surface, material and production defects for components which do not allow automated testing. Or for components where a manual quality inspection is deliberately chosen.

Packaging

We offer packaging solutions to meet your needs

After successful coating and inspection of your components, we wrap your goods fully automatically or manually according to your customer specifications in boxes or small load carriers. The component groups which we assembly manually are packed in customer containers and labelled according to the VDA standard.

In addition, we offer the option of packing and sealing your goods after the “0 error selection” inline and without further handling in foil bags. This protects the components and prevents parts being mixed up during subsequent handling. There are more automatic packaging machines available to pack small parts piece-by-piece in foil bags.

Logistics

We take your product to its destination

In 2014, we successfully implemented the migration of our company software to SAP. We were the first galvanising-based company in the world to network almost all key areas and locations of the WHW Hillebrand Group using SAP. Production processes are simplified and the scheduling of orders optimised. The numerous possibilities in the coating area and the diverse, ever-expanding full service on offer required this change, and it was a great success.

Services, which we offer you in the area of logistics, are taking on forwarding transactions, goods deliveries to and from our consignment warehouses and the picking of your goods.