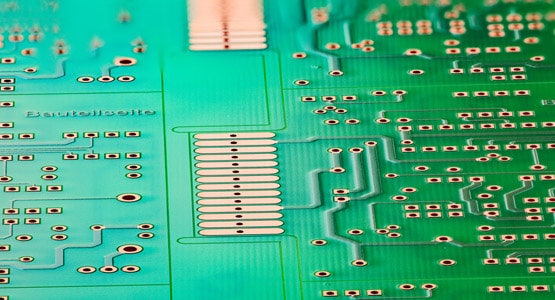

Immersion gold end surface for PCB manufacturing

Immersion gold baths (IG) are used in the ENIG series (electroless nickel/immersion gold). The individual variants can build up a dense gold layer on various nickel alloys (medium and high phos) without corrosion. By using a very low gold content, the variants are very economical. Patented nickel inhibitors ensure that these baths do not produce nickel corrosion and thereby serve as an excellent soldering and bonding joint (solder joint).

System profile

- Patented nickel corrosion inhibitor

- Higher “solder joint” than standard ENIG

- Long service life (> 10 MTO)

- Systems for all NiP alloys

- Low gold content (< 0.5 g/l)

- Around 50 % lower usage costs

- Low gold consumption

- Low layer thickness dispersion and thereby high cost reduction

- Corrosion-free

- Bondable

Application profile

- Low working temperature

IM-GOLD OM

Immersion gold plating on mid-P Ni surfaces Excellent multiple solderability

IM-GOLD OM2

Immersion gold plating on high-P Ni surfaces Excellent multiple solderability