Copper electrolyte for PCB manufacture

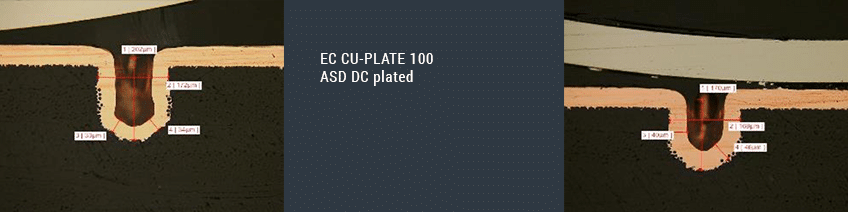

EC CU-PLATE 100 was developed as a high-dispersion copper bath to deposit bright, smooth and fine-crystalline copper layers for manufacturing PCBs. The system can be used horizontally, vertically or in an “airless” way. Here, phosphorous dosed copper anodes (soluble) as well as insoluble mixed oxide anodes (MMO) can be used.

Thanks to its outstanding dispersion even in high current density ranges, it is particularly well suited for plating HDI circuits and high-AR (aspect ratio) circuits. As required for high-end and high-temperature applications, the deposition has convincing physical properties (elongation and tensile strength). Common thermal stress and thermal shock tests are easily passed.

System profile

- Extremely high dispersion in the high current density range.

- Suitable for insoluble and soluble anodes

- Panel and pattern plates

- Suitable for the airless additive system

- Planar deposition

- Superior surface distribution

- Gloss and high ductility over the entire current density range

- High temperature cycling resistance

- Suitable for complex hybrid structures with high material expansion

- Very good compatibility with the direct metallisation process

Application profile

- Can be used vertically and horizontally

- All components can be analysed using CVS and UV-VIS

Galvanic copper bath (direct current)

The EU CU-PLATE 100 is the copper bath for PCB manufacture giving glossy and highly break-proof copper deposits. It does not contain any dye and is sulphur-free. Depending on the tank design, the consumption of EC CU-PLATE 100B and EC CU-PLATE 103L is between 0.05 and 0.2 ml/Ah. EC CU-PLATE 100 creates a very fine surface with a fine crystalline structure. It is particularly well suited for direct metallisation. There are various highly effective acidic cleaners available for EC CU-PLATE.