GC TOP 190

Intermediate sealant for black surfaces

The GC TOP sealing systems developed by Hillebrand Chemicals (Top Coats) offer a wide range of applications for visually attractive surfaces with simultaneously improved corrosion protection. They are designed to be used with GC PASS passivation. On electro depositions the combination of these two coatings influences the chemical and mechanical resistance of the entire system.

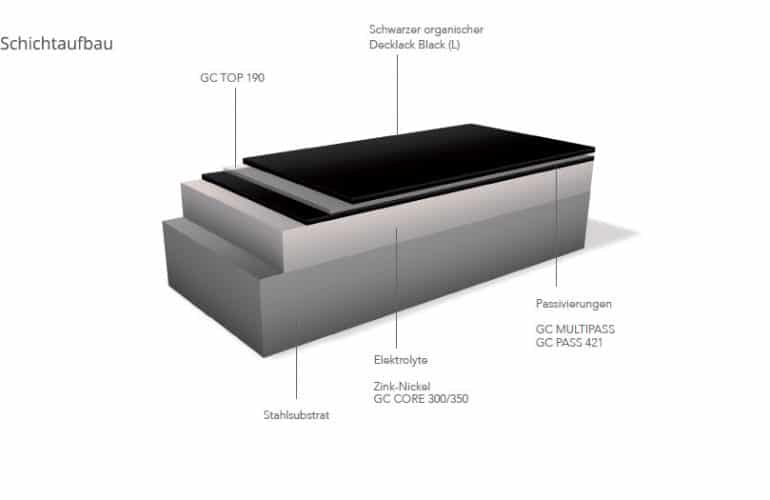

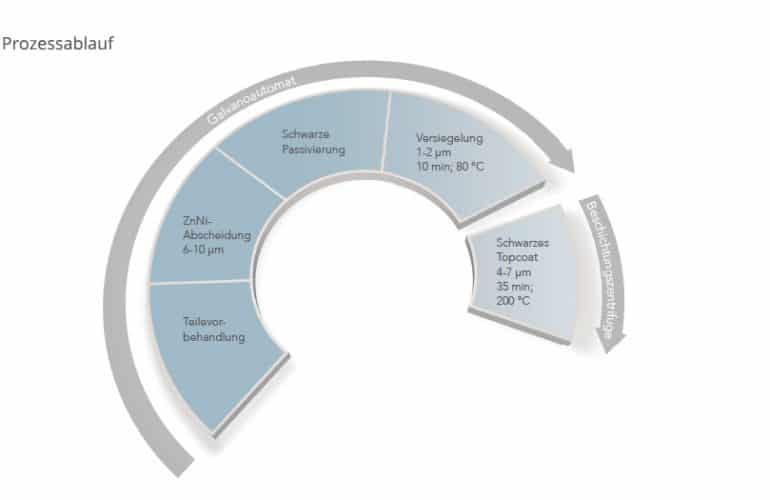

GC TOP 190 is the heart of the Hillebrand Chemicals coating system for high-quality black zinc-nickel surfaces. 6 – 10 µm ZnNi GC CORE 350, plus black Multipass passivation or alternatively, the cobalt-free GC PASS 421.1 passivation, plus conversion sealant GC TOP 190.

With the water-based intermediate sealant, GC TOP 190, it is possible for the first time, to develop a conversion sealant with outstanding properties that act as a link between the passivated zinc alloy layer and the top-coat. It fulfils all multifunctional tasks, without compromising. Extreme adhesion forces bind the top-coat to the zinc alloy layer without fear of delamination.

The electrical separation of the top-coat to the substrate isolates noble pigment components from the zinc-nickel base layer. Premature red rust breakthroughs, as experienced with duplex systems, are thereby systematically avoided. The oxygen diffusion barrier ensures excellent corrosion behaviour without surface changes after 720 hours in accordance with DIN EN ISO 9227. The coating system with a black top-coat also offers very good media resistance and, thanks to the integrated lubricant, matches the friction coefficient interval required by the VDA.

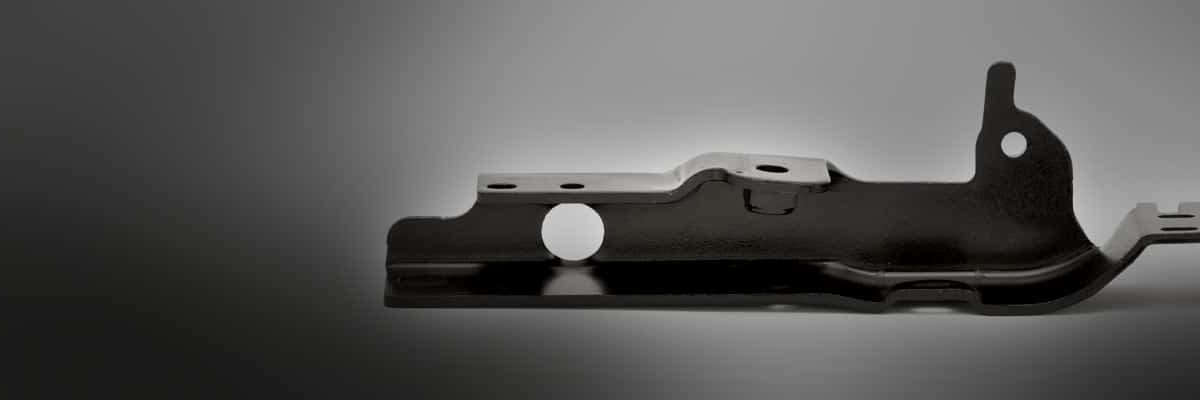

The coating system presented here with the novel conversion sealant GC TOP 190, represents the high-end version of zinc/nickel surfaces. These can easily replace significantly more expensive coating systems.