GC TOP 180

High-end sealant with chemical cross-linkability

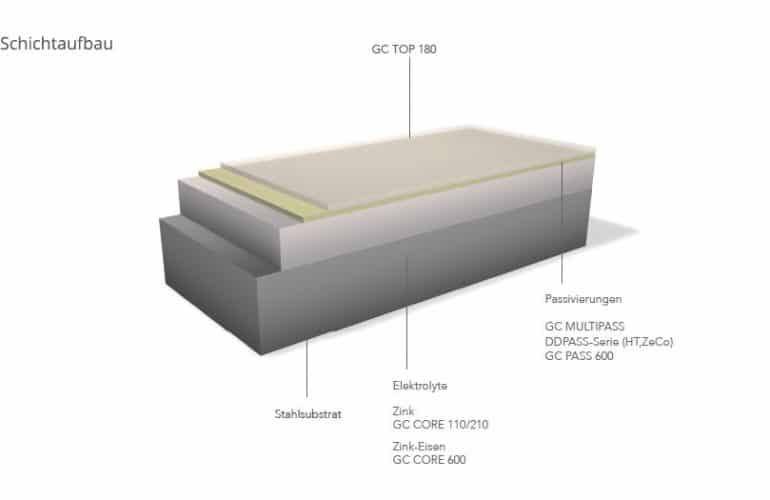

The GC TOP sealing systems developed by Hillebrand Chemicals (Top Coats) offer a wide range of applications for visually attractive surfaces with simultaneously improved corrosion protection. They are designed to be used with GC PASS passivation. On electro depositions the combination of these two coatings influences the chemical and mechanical resistance of the entire system.

GC TOP 180 is a reactive, especially thin layer sealing product. It is water-based and has purely inorganic components. The main area of application includes thick and thin-layer passivated zinc, zinc-iron, and zinc-nickel surfaces in mass produced goods. Layer systems sealed with GC TOP 180 are stable up to a temperature of 220 °C. Zinc surfaces, in particular, experience an extreme increase in corrosion protection thanks to the sealant.

GC TOP 180 can be used as a 30% solution directly in the drum of an automated galvanising system, or as a concentrate in centrifuges.

For the process-safe production, an inline barrel dryer is recommended. The chemical cross-linking of the inorganic sealing components requires a temperature of at least 140 °C. The thermal de-embrittlement stage and chemical cross-linking of the sealing layer should be combined in one process step to use energy efficiently.

The dry film is already distinguished in an extremely thin layer of 300 – 500 nm by a very shiny visual appearance and suppresses irisation effects of the passivation.

Furthermore, a GC TOP 180 closed sealing film considerably delays the formation of white rust on zinc layers and also greying on zinc / nickel layers. The reactive components of the sealing product together with the passivation produce a particularly high performing corrosion protection unit which also offers secure infiltration protection in the event of any damage. The highest corrosion protection is already achieved after drying of 15 minutes at 190 to 210 °C.

Corrosion resistance in accordance with DIN EN ISO 8227 depending on the substrate:

- Zinc, blue passivated, GC TOP 180 WR > 240 h RR > 600 h

- Zinc, thick-layer passivated, GC TOP 180 WR > 300 h RR > 600 h

- Zinc-iron, transparent passivated, GC TOP 180 WR > 300 h RR > 720 h

- Zinc-nickel, transparent passivated, GC TOP 180 WR > 600 h RR > 1500 h