Zinn-Stripper für die Leiterplattenfertigung

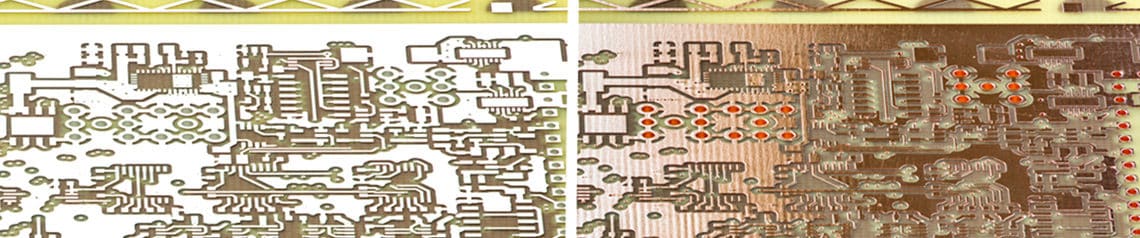

Der EC SN-STRIP HL ist ein einstufiger Stripper auf Salpetersäurebasis. Er wird zur Entfernung von Zinn- sowie Zinn-Blei-Schichten (Metallresist) und der intermetallischen Zone von Kupferflächen und Bohrungen in der Leiterplatten-Fertigung genutzt und weist sich durch eine sehr hohe Metallaufnahme (High Loading) aus.

Mit seiner geringen Oberflächenspannung entfernt er diese Schichten auch aus feinsten Bohrungen. Durch die Verwendung spezieller Inhibitoren bleibt die Kupferfläche glänzend und lässt sich anschließend direkt AOI prüfen.

Durch die rückstandsfreie Entfernung unterstützt EC SN-STRIP HL das fehlerfreie Aufbringen von Endoberflächen wie zum Beispiel ENIG/ENEPIG, iSn, iAg oder iPd.

Systemprofil

- Sehr hohe Metallaufnahme (HL – High Loading)

- Einstufiger Prozess

- Entfernung der intermetallischen Zone inklusive

- Sehr schnelle und konstante Strippgeschwindigkeit

- Geringe Geruchsbelastung (NOx)

- Geringe Niederschlagsbildung

- Keine Kupferoxidation für direkte AO-Inspektion

- Geringer Kupferangriff

- Ammoinium-/Fluorid-/Peroxid-Freies System

- Eine Dosierkomponente

- Einfache Dosierung über Dichtespindel

- Geringe Oberflächenspannung und dadurch gute Benetzung von feinen Bohrungen

Anwendungsprofil

- Geringe Arbeitstemperatur

EC SN-STRIP HL – ZINNSTRIPPER

EC SN-STRIP HL ist ein Zinnstripper auf Salpetersäurebasis für die Leiterplattenfertigung mit einer sehr hohen Metallaufnahme. Er strippt Zinn von Kupferflächen mit einem minimalen Kupferangriff und wird sowohl horizontal als auch vertikal angewendet. Er ist frei von Fluorverbindungen und neigt nicht zur Sedimentation. Durch seine geringe Oberflächenspannung ist er besonders gut für das Strippen von Zinn von Leiterplatten mit hoher Aspect-Ratio geeignet.