Metallisierung für die Leiterplattenfertigung

EC NANOCARBITE LS Prozess ist ein edelmetallfreies, vierstufiges Direktmetallisierungsverfahren auf Graphitbasis. Das System metallisiert zuverlässig, kostengünstig und schnell alle bekannten Leiterplattenmaterialien und Leiterplatten-Konstruktionen.

Der verwendete EC NANOCARBITE LS Conditioner konditioniert die unterschiedlichsten Polymere, Keramiken und Glasqualitäten.

Durch den Einsatz eines Schutzkolloids in der Dispersion ist es stabil gegen die Verunreinigung mit Kationen hoher Valenz. Somit fördert es höchstmögliche und konstante Debye-Länge. Die stabile und geringe Viskosität von < 3 mPas (Dispersion) macht das Kolloid besonders geeignet für den High-End-Einsatz.

Die Verwendung des Compactors ermöglicht dem Verfahren, zuverlässig hochlagige starre und flexible Mulitlayer zu metallisieren. EC NANOCARBITE ist cyanid-, schwermetall-, formaldhyd- und komplexbildnerfrei.

Systemprofil

- Durchmetallisierung aller Materialien und Konstruktionen

- Cyanid-, formaldehyd-, komplexbilder- und schwermetallfrei

- Umwelt- und ressourcenschonendes Verfahren

- Geringe Viskosität (<10 mPas) der Dispersion

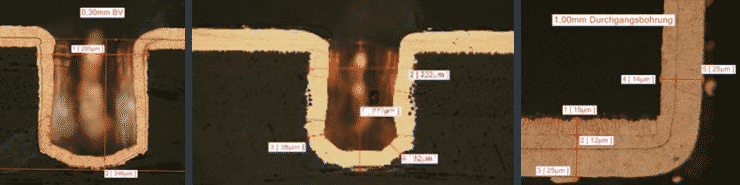

- HDI- und Blind-Via-kompatibel

- Robuste und entwickelbare Leitschicht

- Alterungsstabiler (>6 Wochen) ultraschallunterstützter Conditioner

- Stabilisiertes Graphitkolloid

- Compactorsystem für HDI und hochlagige Multilayer

- Niedriger Feststoffgehalt

Anwendungsprofil

- Horizontal und vertikal anwendbar

- Geringer Analyseaufwand (< 20 Minuten pro Tag)

- Extrem schnelle Prozesszeit von < 10 Minuten

EC NANOCARBITE LS Conditioner – Kohlenstoff-Conditioner

Für die Vorbereitung der Bohrungen vor der Kohlenstoff/Graphit-Aufnahme wurde dieser Conditioner entwickelt. Er hinterlässt eine sehr hohe Ladungsdichte auf der Glas/Harz-Matrix, wodurch die darauffolgende Kohlenstoffstufe mit einem geringeren Feststoffgehalt angewendet werden kann. Anwendungen, in denen 2-5 Gew.% empfohlen sind, kommen mit dem LS(LowSolids)-Conditioner mit lediglich 2-3,5 Gew.% aus. Dadurch kann die Ätzrate reduziert und das Risiko von Ring-Voids sowie die Rückätzung bei =<18 μm Innenlagen deutlich minimiert werden. Durch eine homogene Abscheidung fördert der EC NANOCARBITE LS Conditioner die Haftung der Kupferhülse. Der bekannte Leistungsverlust, wie zum Beispiel die Belegung von Flächen oder Blind Vias, sind beim EC NANOCARBITE LS Conditioner selbst nach einigen Produktionsstunden nicht zu beobachten. Er ist folglich ein sehr stabiles System.

EC NANOCARBITE LS Dispersion – Kohlenstoff-Dispersion

EC NANOCARBITE LS Dispersion ist ein stabiles und hochfeines Graphitkolloid. Die Abscheidung ist hochleitend und exzellent plattierbar. Es scheidet sich auf der konditionierten Lochwand gleichmäßig ab und ist sowohl leitend als auch haftvermittelnd. EC NANOCARBITE LS Dispersion ist für gängige Leiterplattenkonstruktionen geeignet.

EC NANOCARBITE LS Verdichter – Kohlenstoff-Verdichter

Dieser hocheffektive Verdichter und Vernetzer von elektrostatisch gebundenem Kohlenstoff wurde entwickelt, um eine haftfeste und leitende Kohlenstoffschicht auf der Glas/Harz-Matrix einer Leiterplatte aufzubringen. Durch die verdichtende Eigenschaft entsteht eine vernetzte, gleichmäßige und elektrisch leitende Leitschicht, die dabei hochdicht ist.