HIGHCOR

Maximum corrosion protection on zinc surfaces

Process: Zinc acidic + polymerisation Application: Barrel application

The zinc polymerisation system, HIGHCOR, from WHW Hillebrand is characterized by a uniform layer thickness distribution and reliable corrosion protection for the coating of mass-produced goods. The system consists of a metal coating from a weakly acidic or alkaline electrolyte, a thick-layer passivation, and a specially developed polymerisation sealant which is activated by thermal post-treatment.

Both the corrosion protection and resistance to mechanical loads are significantly increased. The HIGHCOR sealing process reacts with the thick-layer passivation and forms a protective layer. The frictional coefficient can be adjusted according to the international standards of the automotive industry for connecting elements.

- Maximum corrosion protection on zinc surfaces

- Very good cost-effectiveness

- Attractive appearance

- Simple use

- Environmentally friendly through solvent-free production

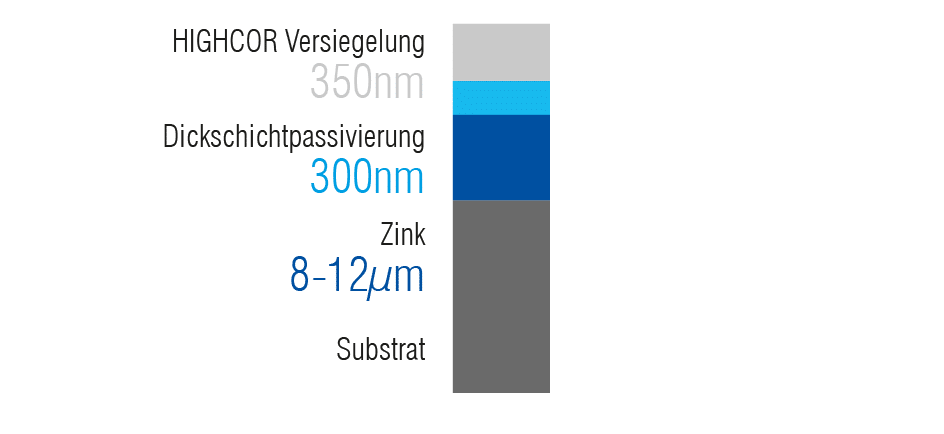

Layer structure

The layer structure of HIGHCOR consists of an 8 to 12 µm electrodeposited zinc layer (depending on the required corrosion protection), a 300 nm thick-layer passivation, which protects the substrate from white rust corrosion, and an in-house developed, pure inorganic HIGHCOR sealant, which is activated by the input of energy (heat), polymerises and which then produces an excellent barrier protection despite the thinness of its layer. Optionally, slip coatings can be applied to adjust the friction coefficient for connecting elements.

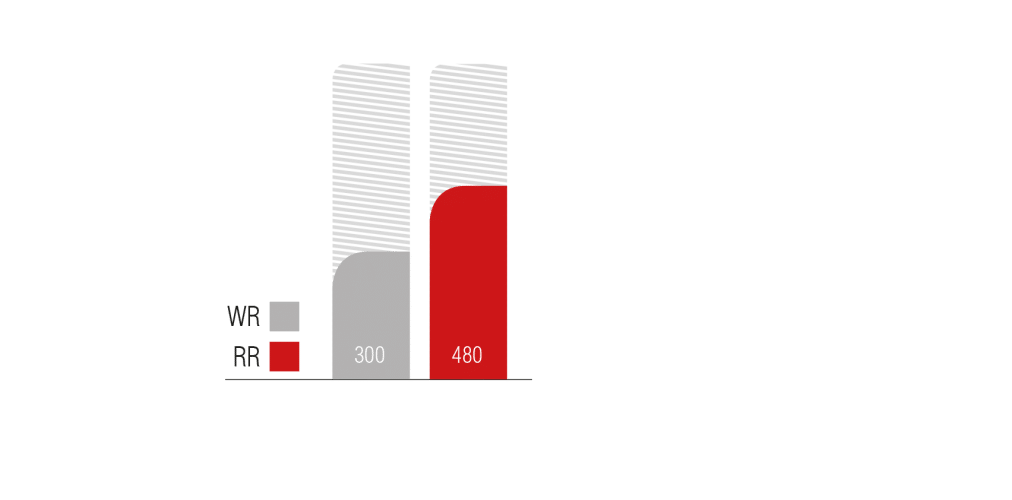

Corrosion protection