EC RESIN-ETCH

Permanganate-based de-smear system for PCB manufacture

The EC RESIN (ETCH/SOLV/N) de-smear system is a 3-stage de-smear system for horizontal and vertical application. The system uses a biodegradable swelling agent and reliably de-smears / structures many polymers at low temperatures with short exposure times.

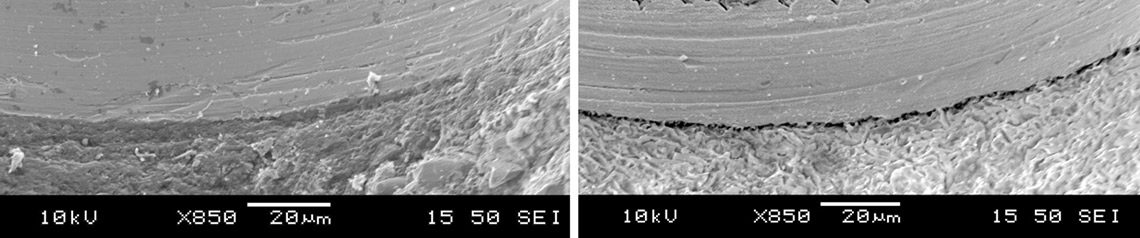

The system leaves a clean and defined structures glass / resin matrix, clean inner layer connections and hole edges. The micro-roughness and inner layer cleaning achieved by EC RESIN-ETCH products are ideally suited for the subsequent application of the conductive layer by direct metallisation or the chemical copper process.

For stable process management and constant etch-back, we recommend the regeneration unit supplied by Hillebrand Chemicals.

System profile

- Biodegradable swelling agent (EC RESIN-SOLV 01)

- 3-Step process to de-smear or create an etch-back

- Very long service life

- Regenerative oxidant thanks to electrochemical regeneration cell from Hillebrand Chemicals GmbH

- Hydrolysis-stable swelling system

- Works on FR4, FR5, tetra, poly-functional resins as well as poly-amide

- No field variations as would be found with the plasma process

- Construction of optimal resin topography for an optimal connection

- Liquid and solid oxidiser for optimal de-smearing and a concentration adjustment for different laminates (EC RESIN-ETCH 01/03)

- Reducing agent / neutraliser without copper attack (EC RESIN-ETCH N)

Application profile

- Can be applied horizontally and vertically

- Low working temperature

ECRESIN-SOLV 01 – Swelling agent

EC RESIN-SOLV 01 is biodegradable , speccially developed for PCB manufacture. When used together with EC RESIN-ETCH, EC RESIN-SOLV 01 swells resin smears and thereby guarantees effective and consistent de-smearing and etch-back. The swelling agent is just as effective with FR-4, FR-5, di, tetra, poly-functional resins and poly-amide resin systems (also MDA free ones). In addition, it is also very easy to control and to expand.

EC RESIN-ETCH 01 – Liquid permanganate

The de-smear system using permanganate-based EC RESIN-ETCH 01 (liquid) is used to de-smear and/or etch bore hole walls on PCBs. The resulting polymer topography promotes the adhesion of the subsequent conductive layers. The system works on different polymers and can be used in high concentrations.

EC RESIN-ETCH 02 – Base

EC RESIN-ETCH 03 – Solid permanganate

The de-smear system using EC RESIN-ETCH 03 (solid) is a permanganate based de-smear process. It is used to de-smear and/or etch the bore hole walls on PCBs. The resulting polymer topography promotes the adhesion of the subsequent conductive layers.

EC RESIN-ETCH N – Neutraliser

EC RESIN-ETCH N is the final stage in the EC RESIN-ETCH series and prepares the hole wall for conditioning. It reduces residual manganese residues to soluble Mn2+ and leaves a purified glass / polymer matrix behind. EC RESIN-ETCH N is peroxide and fluoride-free. EC RESIN-ETCH N does not etch copper and thereby prevents the risk of negative etch-back. The product prevents algae formation in subsequent rinses.