Highest corrosion protection with deep black appearance

Process: Zinc-nickel + EDP Application: Rack application

The DUPLEX coating system consists of a zinc-nickel layer with an electrophoretically applied black dip paint. It offers maximum protection with a low total layer thickness, even during mechanical reworking or where there is mechanical damage, such as due to stone chipping. Depending on the article geometry, the ZnNi coating, including the conversion layer, is applied in a barrel or on a rack. The cataphoretic dip coating is applied in a horizontal coating system for rack-like mass production on a universal carrier.

DUPLEX is excellently suited for lock parts, hinge elements, engine bay materials and safety parts.

• Deep black appearance • Highest corrosion protection • Heat resistant up to 180 °C • Very ductile • Can be reshaped and crimped in most applications without loss of functional properties

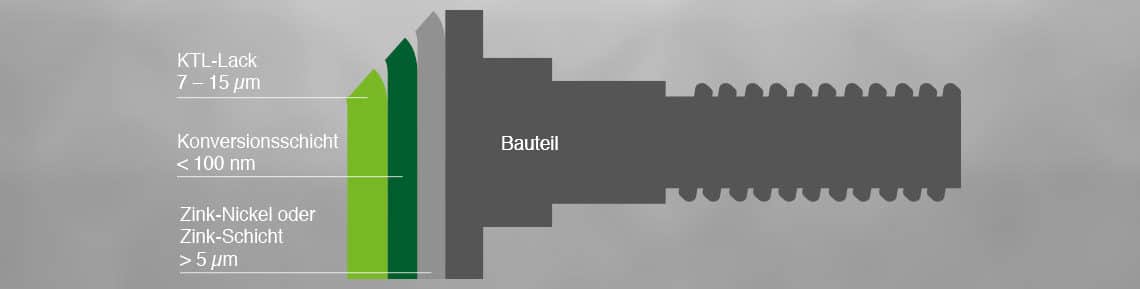

Layer structure

DUPLEX is characterised by its very thin and uniform layer. Even challenging geometries, inner areas of hollow bodies with through-holes, as well as internal drives and threads can be homogeneously coated due to the very good edge access. Tolerances are easily met.

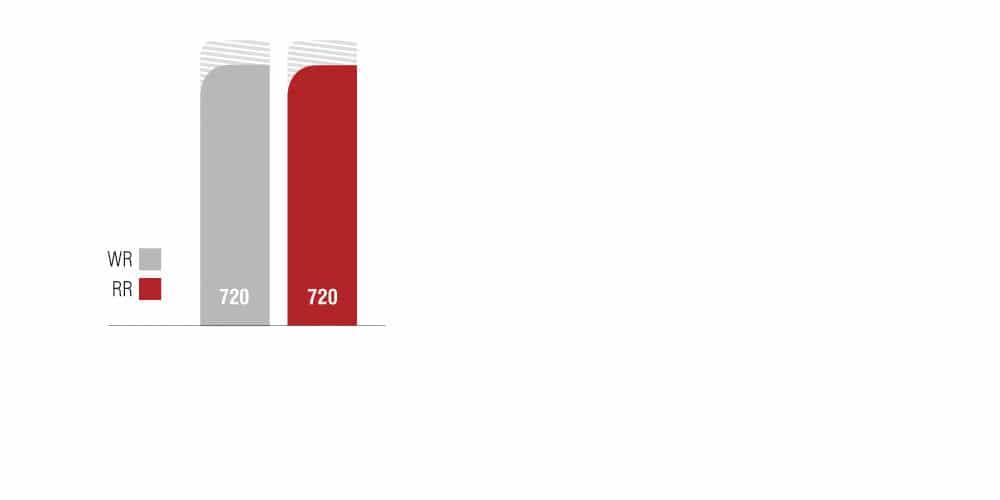

Corrosion protection

With DUPLEX, we offer you a corrosion protection system which protects against corrosion both actively and passively and is far superior to many other surfaces. Even at temperatures of up to 180 °C, such as might be found in an engine bay, DUPLEX shows excellent white rust resistance.